Page 197 - needle bearings

P. 197

Clearance-adjustable needle roller bearings

NTN

How to adjust radial clearance

The ratio of outer ring axial shrinkage to shrinkage of

roller inscribed circle diameter (Fw) is nearly 3:1. In other 2

words, the outer ring must be tightened by 3 mm in axial 1

direction to make the radial clearance smaller by 1 mm.

For adjustment of the radial clearance, the outer ring

must be tightened uniformly in parallel to the shaft center.

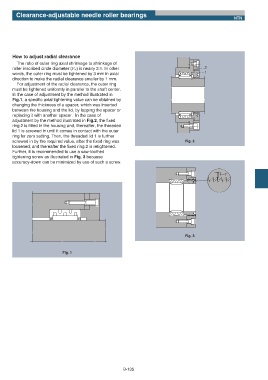

In the case of adjustment by the method illustrated in

Fig.1, a specific axial tightening value can be obtained by

changing the thickness of a spacer, which was inserted

between the housing and the lid, by lapping the spacer or

replacing it with another spacer. In the case of

adjustment by the method illustrated in Fig.2, the fixed

ring 2 is fitted in the housing and, thereafter, the threaded

lid 1 is screwed in until it comes in contact with the outer

ring for zero setting. Then, the threaded lid 1 is further

screwed in by the required value, after the fixed ring was Fig. 2

loosened, and thereafter the fixed ring 2 is retightened.

Further, it is recommended to use a saw-toothed

tightening screw as illustrated in Fig. 3 because

accuracy-down can be minimized by use of such a screw.

4ʙ7˚

Fig. 3

Fig. 1

B-135