Page 34 - needle bearings

P. 34

Bearing Internal Clearance

NTN

5. Bearing Internal Clearance

5.1 Radial clearance 5.2 Running clearance

Radial clearance in bearing (initial radial clearance) 5.2.1 Setting up running clearance

means the displacement value of bearing ring when the Bearing clearance in running, that is, running clearance

non-fixed ring was displaced in radial direction with either gets generally smaller than the initial radial clearance,

one of the inner ring and outer ring remained fixed, before depending on the fits and temperature difference

the bearing is installed on a shaft or in a housing. between the inner ring and the outer ring. This running

clearance must be set up optimally because setting up it

Machined ring needle roller bearing (with inner ring) ; improperly would lead to shorter life, overheat and

The initial clearance values for this bearing type are as vibration or running noise of bearing.

shown in Table 5.1. Table 5.1 (1) shows the Theoretically the bearing life comes to the maximum

interchangeable clearances, which are remained when the running clearance of bearing in normal running

unchanged even after inner ring or outer ring was is slightly negative, but it is difficult to always hold this

reassembled in. Table 5.1(2) shows non-interchangeable optimal condition during actual running. If the negative

clearances, which do not allow reassembly of inner ring clearance value gets larger due to change of somewhat

or outer ring due to the narrow clearance range. The operating condition, it would cause significant reduction

bearing clearances are represented by the symbols of of bearing lifetime and overheat. To avoid such

C2, ordinary, C3 and C4 in the order from the smallest phenomena, generally proper initial radial clearance is

one and the non-interchangeable clearance symbols are selected and set up so the running clearance gets slightly

followed by "NA" for identification. larger than 0 (zero).

For the radial clearance values for bearing types In the case of usual operating conditions, in other words,

other than the machined ring needle roller bearings, application of the fits based on ordinary load, usual

refer to "Commentary" described in the respective rotational speed and running temperature, etc., an

Dimensions Table. optimal running clearance can be got by selecting an

ordinary clearance.

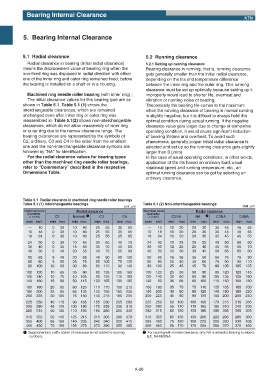

Table 5.1 Radial clearance in machined ring needle roller bearings

Table 5.1 (1) Interchangeable bearings Table 5.1 (2) Non-interchangeable bearings

Unit Жm Unit Жm

Nominal bore Radial clearance Nominal bore Radial clearance

diameter diameter

d (mm) C2 Normal 1 C3 C4 d (mm) C2NA NA 2 C3NA C4NA

over incl. min max min max min max min max over incl. min max min max min max min max

ʕ 10 0 30 10 40 25 55 35 65 ʕ 10 10 20 20 30 35 45 45 55

10 18 0 30 10 40 25 55 35 65 10 18 10 20 20 30 35 45 45 55

18 24 0 30 10 40 25 55 35 65 18 24 10 20 20 30 35 45 45 55

24 30 0 30 10 45 30 65 40 70 24 30 10 25 25 35 40 50 50 60

30 40 0 35 15 50 35 70 45 80 30 40 12 25 25 40 45 55 55 70

40 50 5 40 20 55 40 75 55 90 40 50 15 30 30 45 50 65 65 80

50 65 5 45 20 65 45 90 65 105 50 65 15 35 35 50 55 75 75 90

65 80 5 55 25 75 55 105 75 125 65 80 20 40 40 60 70 90 90 110

80 100 10 60 30 80 65 115 90 140 80 100 25 45 45 70 80 105 105 125

100 120 10 65 35 90 80 135 105 160 100 120 25 50 50 80 95 120 120 145

120 140 10 75 40 105 90 155 115 180 120 140 30 60 60 90 105 135 135 160

140 160 15 80 50 115 100 165 130 195 140 60 35 65 65 100 115 150 150 180

160 180 20 85 60 125 110 175 150 215 160 180 35 75 75 110 125 165 165 200

180 200 25 95 65 135 125 195 165 235 180 200 40 80 80 120 140 180 180 220

200 225 30 105 75 150 140 215 180 255 200 225 45 90 90 135 155 200 200 240

225 250 40 115 90 165 155 230 205 280 225 250 50 100 100 150 170 215 215 265

250 280 45 125 100 180 175 255 230 310 250 280 55 110 110 165 185 240 240 295

280 315 50 135 110 195 195 280 255 340 280 315 60 120 120 180 205 265 265 325

315 355 55 145 125 215 215 305 280 370 315 355 65 135 135 200 225 295 295 360

355 400 65 160 140 235 245 340 320 415 355 400 75 150 150 225 255 330 330 405

400 450 70 190 155 275 270 390 355 465 400 450 85 170 170 255 285 370 370 455

1 Supplementary suffix codes of clearance is not added to bearing 2 For bearing with normal clearance, only NA is added to bearing numbers.

numbers. EX. NA4920NA

A-30