Page 101 - domce

P. 101

2 INSERT BALL BEARINGS

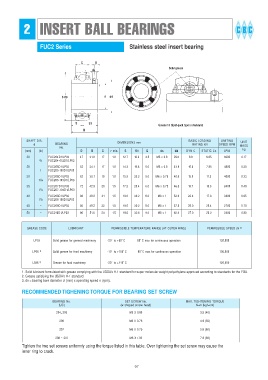

FUC2 Series Stainless steel insert bearing

C G

Solid grease

ds

r

S D d d4

S S1

Grease fill (Spot-pack type is standard)

B

S H A F T . A I D M I D E N O I S N S m m B A C I S L O A N I D G N I T I M I L G U T I N

d B E A N I R G R A N I T G k N S P E E D R P M M A S S

N . o

m ( ) m ) n i ( D B C r n i m S S 1 G d s d 4 D Y N C S T A C I T C o L P 3 0 g k

0 2 F U C 4 0 2 D L / 1 P 3 0 7 4 0 . 1 3 7 1 0 . 1 7 . 2 1 3 . 8 1 5 . 4 M 5 x 8 . 0 6 . 9 2 9 . 9 5 6 . 6 0 0 0 6 7 1 . 0

3 F U C 2 1 0 - 4 0 2 D L / 1 P 3 0

/4

5 2 F U C 5 0 2 D L / 1 P 3 0 2 5 1 . 4 3 7 1 0 . 1 3 . 4 1 8 . 9 1 0 . 5 M 5 x 8 . 0 9 . 3 3 8 . 0 1 5 8 . 7 0 0 8 4 0 2 . 0

1 F U C 0 0 1 - 5 0 2 D L / 1 P 3 0

0 3 F U C 6 0 2 D L / 1 P 3 0 2 6 1 . 8 3 9 1 0 . 1 9 . 5 1 2 . 2 2 0 . 5 M 6 x 5 7 . 0 8 . 0 4 0 . 5 1 3 . 1 1 0 0 0 4 3 3 . 0

3 F U C 3 0 1 - 6 0 2 D L / 1 P 3 0

1 / 61

5 3 F U C 7 0 2 D L / 1 P 3 0 2 7 9 . 2 4 0 2 5 . 1 5 . 7 1 4 . 5 2 0 . 6 M 6 x 5 7 . 0 8 . 6 4 7 . 9 1 3 . 5 1 0 0 4 3 9 4 . 0

1 F U C 4 0 1 - 7 0 2 D L / 1 P 3 0

1 /4

0 4 F U C 8 0 2 D L / 1 P 3 0 0 8 2 . 9 4 1 2 5 . 1 0 . 9 1 2 . 0 3 0 . 8 M 8 x 1 0 . 3 5 4 . 2 2 8 . 7 1 0 0 0 3 5 6 . 0

1 F U C 8 0 1 - 8 0 2 D L / 1 P 3 0

1 /2

5 4 – F U C 9 0 2 D L / 1 P 3 0 5 8 2 . 9 4 2 2 5 . 1 0 . 9 1 2 . 0 3 0 . 8 M 8 x 1 5 . 7 5 0 . 5 2 4 . 0 2 0 0 7 2 0 7 . 0

0 5 – F U C 0 1 2 D L / 1 P 3 0 0 9 6 . 1 5 4 2 5 . 1 0 . 9 1 6 . 2 3 0 . 9 M 8 x 1 4 . 2 6 0 . 7 2 2 . 3 2 0 0 4 2 0 8 . 0

G R E A S E C O D E L U B C I R A N T P E R S I M B I S L E T E M P E R A T U R E R A N G E A ( T O U T E R N I R ) G P E R S I M B I S L E S P E E D n d ) 3

L P 3 0 S d i l o e s a e r g r o f l a r e n e g m y r e n i h c a ˜ 0 2 - o t ˚ 0 8 + C ˚ 0 6 C m r o f x a s u o u n i t n o c n o i t a r e p o 0 0 0 , 0 2 1

L P 6 0 ) 1 S d i l o e s a e r g d o o f r o f m y r e n i h c a ˜ 0 1 - o t ˚ 0 0 1 + C ˚ 0 8 C m r o f x a s u o u n i t n o c n o i t a r e p o 0 0 0 , 0 0 1

6 9 5 L ) 2 e s a e r G d o o f r o f m y r e n i h c a ˜ 0 2 - o t ˚ 0 1 1 + C _ 0 0 0 , 0 2 1

1. Solid lubricant formulated with grease complying with the USDA’s H-1 standard for super molecular weight polyethylene approved according to standards for the FDA.

2. Grease satisfying the USDA’s H-1 standard.

3. dn = bearing bore diameter d (mm) x operating speed n (rpm).

RECOMMENDED TIGHENING TORQUE FOR BEARING SET SCREW

B E A N I R G N . o S E T S C R E W N . o M A . X G I T H T E N I N G T O R Q U E

U ( ) C w ( d e p a h s e r c s w ) d a e h N = m c = f g k ( ) m

, 4 0 2 5 0 2 M 5 X 0 8 . 0 9 . 3 ) 0 4 (

6 0 2 M 6 X 5 7 . 0 9 . 4 ) 0 5 (

7 0 2 M 6 X 5 7 . 0 8 . 5 ) 0 6 (

8 0 2 ~ 0 1 2 M 8 X 0 0 . 1 8 . 7 ) 0 8 (

Tighten the two set screws uniformly using the torque listed in this table. Over tightening the set screw may cause the

inner ring to crack.

97