Page 146 - domce

P. 146

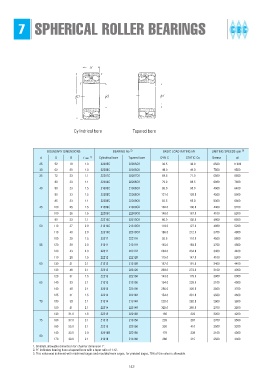

7 SPHERICAL ROLLER BEARINGS

TO COME To come

Cylindrical bore Tapered bore

B O U N D A R Y M I D E N O I S N S B E A N I R G N o ) 2 B A C I S L O A D R A N I T G k N N I T I M I L G S P E E D S p r m ) 3

d D B r m n i ) 1 C e r o b l a c i r d n i l y d e r e p a T e r o b D Y N C S T A C I T C o e s a e r G l i o

5 2 2 5 8 1 0 . 1 5 0 2 2 2 C 5 0 2 2 2 C K 5 . 6 3 0 . 6 3 0 0 5 8 0 0 0 1 1

0 3 2 6 0 2 0 . 1 6 0 2 2 2 C 6 0 2 2 2 C K 0 . 9 4 0 . 9 4 0 0 5 7 0 0 5 9

5 3 2 7 3 2 1 . 1 7 0 2 2 2 C 7 0 2 2 2 C K 5 . 9 6 0 . 1 7 0 0 5 6 0 0 5 8

0 8 3 2 1 . 1 8 0 2 2 2 C 8 0 2 2 2 C K 0 . 9 7 5 . 8 8 0 0 0 6 0 0 6 7

0 4 0 9 3 2 5 . 1 8 0 3 1 2 C 8 0 3 1 2 C K 0 . 8 8 0 . 0 9 0 0 9 4 0 0 4 6

0 9 3 3 5 . 1 8 0 3 2 2 C 8 0 3 2 2 C K 0 . 1 2 1 0 . 8 2 1 0 0 5 4 0 0 9 5

5 8 3 2 1 . 1 9 0 2 2 2 C 9 0 2 2 2 C K 5 . 2 8 0 . 5 9 0 0 3 5 0 0 8 6

5 4 0 0 1 5 2 5 . 1 9 0 3 1 2 C 9 0 3 1 2 C K 0 . 2 0 1 0 . 6 0 1 0 0 4 4 0 0 7 5

0 0 1 6 3 5 . 1 9 0 3 2 2 C 9 0 3 2 2 C K 0 . 8 4 1 0 . 7 6 1 0 0 1 4 0 0 3 5

0 9 3 2 1 . 1 0 1 2 2 2 C 0 1 2 2 2 C K 0 . 6 8 0 . 2 0 1 0 0 9 4 0 0 3 6

0 5 0 1 1 7 2 0 . 2 0 1 3 1 2 C 0 1 3 1 2 C K 0 . 8 1 1 0 . 7 2 1 0 0 0 4 0 0 2 5

0 1 1 0 4 0 . 2 0 1 3 2 2 C 0 1 3 2 2 C K 0 . 6 8 1 0 . 2 1 2 0 0 7 3 0 0 8 4

0 0 1 5 2 5 . 1 1 1 2 2 2 1 1 2 2 2 K 5 . 3 9 0 . 0 1 1 0 0 5 4 0 0 8 5

5 5 0 2 1 9 2 0 . 2 1 1 3 1 2 1 1 3 1 2 K 0 . 5 4 1 0 . 3 6 1 0 0 7 3 0 0 8 4

0 2 1 3 4 0 . 2 1 1 3 2 2 1 1 3 2 2 K 0 . 4 0 2 0 . 4 3 2 0 0 4 3 0 0 4 4

0 1 1 8 2 5 . 1 2 1 2 2 2 2 1 2 2 2 K 0 . 5 1 1 0 . 7 4 1 0 0 1 4 0 0 3 5

0 6 0 3 1 1 3 1 . 2 2 1 3 1 2 2 1 3 1 2 K 0 . 7 6 1 0 . 1 9 1 0 0 4 3 0 0 4 4

0 3 1 6 4 1 . 2 2 1 3 2 2 2 1 3 2 2 K 0 . 8 3 2 0 . 3 7 2 0 0 1 3 0 0 0 4

0 2 1 1 3 5 . 1 3 1 2 2 2 3 1 2 2 2 K 0 . 3 4 1 0 . 9 7 1 0 0 9 3 0 0 0 5

5 6 0 4 1 3 3 1 . 2 3 1 3 1 2 3 1 3 1 2 K 0 . 4 9 1 0 . 8 2 2 0 0 1 3 0 0 0 4

0 4 1 8 4 1 . 2 3 1 3 2 2 3 1 3 2 2 K 0 . 5 6 2 0 . 0 2 3 0 0 8 2 0 0 7 3

5 2 1 1 3 5 . 1 4 1 2 2 2 4 1 2 2 2 K 0 . 4 5 1 0 . 1 0 2 0 0 5 3 0 0 6 4

0 7 0 5 1 5 3 1 . 2 4 1 3 1 2 4 1 3 1 2 K 0 . 0 2 2 0 . 2 6 2 0 0 9 2 0 0 8 3

0 5 1 1 5 1 . 2 4 1 3 2 2 4 1 3 2 2 K 0 . 5 2 3 0 . 0 8 3 0 0 7 2 0 0 5 3

0 3 1 0 . 1 3 5 . 1 5 1 2 2 2 5 1 2 2 2 K 6 6 1 3 2 2 0 0 2 3 0 0 2 4

5 7 0 6 1 0 . 7 3 1 . 2 5 1 3 1 2 5 1 3 1 2 K 9 3 2 7 8 2 0 0 7 2 0 0 5 3

0 6 1 0 . 5 5 1 . 2 5 1 3 2 2 5 1 3 2 2 K 0 3 3 0 1 4 0 0 5 2 0 0 2 3

0 4 1 0 . 3 3 0 . 2 6 1 2 2 2 B 6 1 2 2 2 K 9 7 1 9 3 2 0 0 1 3 0 0 0 4

0 8

0 7 1 0 . 9 3 1 . 2 6 1 3 1 2 6 1 3 1 2 K 0 6 2 5 1 3 0 0 5 2 0 0 3 3

1. Smallest allowable dimension for chamfer dimension ‘r’.

2. ‘K’ indicates bearing have a tapered bore with a taper ratio of 1:12.

3. This value was achieved with machined cages and moulded resin cages; for pressed cages, 75% of the value is allowable.

142