Page 94 - domce

P. 94

2 2 INSERT BALL BEARINGS

NTN Triple-sealed bearings for bearing units

DUSTPROOFING EFFECTIVENESS

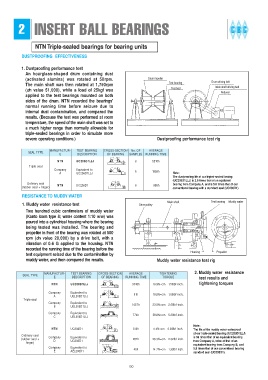

1. Dustproofing performance test

An hourglass-shaped drum containing dust

(activated alumina) was rotated at 50rpm. Drum impeller

Test bearing Drum driving belt

The main shaft was then rotated at 1,750rpm

Test bed Main shaft driving belt

(dn value 51,000), while a load of 25kgf was

Reducer

applied to the test bearings mounted on both

sides of the drum. NTN recorded the bearings’

normal running time before seizure due to

internal dust contamination, and compared the

results. (Because the test was performed at room

temperature, the speed of the main shaft was set to

a much higher range than normally allowable for

triple-sealed bearings in order to simulate more

severe operating conditions.) Dustproofing performance test rig

M A N U F A C T U - R T E S T B E A N I R G C R O S S - S E C O I T N N . o O F A V E R A G E

S E A L T Y P E

E D E S C P I R O I T N O F B E A N I R G S A M P L E S R U N N I N G M I T E

N T N U C 6 0 2 D L 1 J L 3 h 0 1 5 5

l a e s - e l p i r T

C o m y n a p o t t n e l a v i u q E 6 h 9 5 9 1

A U C 6 0 2 D J L L 1 Note:

The dustproofing life of our tripled-sealed beaing

(UC206D1LLJ) is 2.8 times that of an equilalent

y r a n i d r O l a e s bearing from Company A, and is 5.6 times that of our

r e b b u r ( + l a e s ) r e g n i f N T N U C 6 0 2 D 1 6 h 6 8 9 conventional bearing with a standard seal (UC206D1).

RESISTANCE TO MUDDY WATER

Main shaft Test bearing Muddy water

1. Muddy water resistance test Drive pulley

Two hundred cubic centimeters of muddy water

(Kanto loam type 8; water content 1:10 w/w) was

poured into a cylindrical housing where the bearing

being tested was installed. The bearing and

propeller in front of the bearing was rotated at 500

rpm (dn value 20,000) by a drive belt, with a

vibration of 0.6 G applied to the housing. NTN

recorded the running time of the bearing before the

Housing Propellor

test equipment seized due to the contamination by

muddy water, and then compared the results. Muddy water resistance test rig

M A N U F A C T U - R T E S T B E A N I R G C R O S S - S E C O I T N A V E R A G E G I T H T E N I N G 2. Muddy water resistance

S E A L T Y P E

E D E S C P I R O I T N O F B E A N I R G R U N N I N G M I T E T O R Q U E test results and

N T N U C 8 0 2 D L 1 J L h 6 1 0 3 9 . 6 1 N c = m . h c n i - f b l 0 5 . 1 tightening torques

C o m y n a p o t t n e l a v i u q E h 1 5 8 . 8 1 N c = m . h c n i - f b l 6 6 . 1

A U 8 0 2 L E D J L L 1

l a e s - e l p i r T

C o m y n a p o t t n e l a v i u q E h 7 3 4 1 5 . 3 2 N c = m . h c n i - f b l 8 0 . 2

B U 8 0 2 L E D J L L 1

C o m y n a p o t t n e l a v i u q E h 4 7 7 8 . 8 5 N c = m . h c n i - f b l 0 2 . 5

C U 8 0 2 L E D J L L 1

Note:

N T N U C 8 0 2 D 1 h 3 1 5 4 . 4 N c = m . h c n i - f b l 9 3 . 0 The life of the muddy water waterproof

of our triple-sealed bearing (UC208D1LLJ)

y r a n i d r O l a e s

r e b b u r ( + l a e s C o m D y n a p U C 8 0 2 D 1 o t t n e l a v i u q E h 7 8 2 3 . 6 2 N c = m . h c n i - f b l 2 3 . 2 is 59 times that of an equivalent bearing

from Company A, twice of that of an

) r e g n i f

equivalent bearing from Company B, and

C o m y n a p o t t n e l a v i u q E h 0 4 7 . 4 1 N c = m . h c n i - f b l 0 3 . 1 5.9 times that of our conventional bearing

E A 8 0 2 L E D 1 standard seal (UC208D1).

90