Page 226 - needle bearings

P. 226

Roller followers: Yoke-type track rollers

NTN

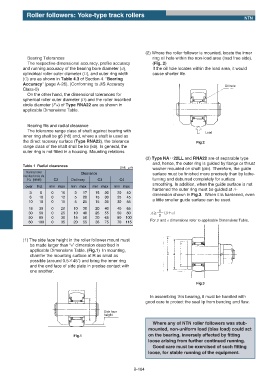

(2) Where the roller follower is mounted, locate the inner

Bearing Tolerances ring oil hole within the non-load area (load free side).

The respective dimensional accuracy, profile accuracy (Fig. 2)

and running accuracy of the bearing bore diameter (d), If the oil hole locates within the load area, it would

cylindrical roller outer diameter (D), and outer ring width cause shorter life.

(C) are as shown in Table 4.3 of Section 4. "Bearing

Accuracy" (page A-26). (Conforming to JIS Accuracy

Oil hole

Class-0)

On the other hand, the dimensional tolerances for

spherical roller outer diameter (D) and the roller inscribed

circle diameter (FW) of Type RNA22 are as shown in

applicable Dimensions Table.

Bearing fits and radial clearance

The tolerance range class of shaft against bearing with Load

inner ring shall be g6 (h6) and, where a shaft is used as

the direct raceway surface (Type RNA22), the tolerance Fig.2

range class of the shaft shall be k5 (k6). In general, the

outer ring is not fitted in a housing. Mounting relations

(3) Type NAŋŋŋŋ22LL and RNA22 are of separable type

and, hence, the outer ring is guided by flange or thrust

Table 1 Radial clearances

Unit: Жm washer mounted on shaft (pin). Therefore, the guide

Nominal roller Clearance

inscribed circle dia. surface must be finished more precisely than by lathe-

Fw (mm) C2 Ordinary C3 C4 turning and deburred completely for surface

smoothing. In addition, when the guide surface is not

over Incl. min max min max min max min max

hardened the outer ring must be guided at A-

3 6 0 10 3 17 15 30 20 40 dimension shown in Fig.3. When it is hardened, even

6 10 0 12 5 20 15 30 25 45

10 18 0 15 5 25 15 35 30 55 a little smaller guide surface can be used.

18 30 0 20 10 30 20 40 40 65

1

30 50 0 25 10 40 25 55 50 80 AʾʕʕʢDʴeʣ

2

50 80 0 30 15 50 30 65 60 100

80 100 0 35 20 55 35 75 70 115 For D and e dimensions refer to applicable Dimensions Table.

(1) The side face height in the roller follower mount must

be made larger than “e” dimension described in

applicable Dimensions Table. (Fig.1) In mounting,

chamfer the mounting surface at R as small as

possible (around 0.5ʷ45˚) and bring the inner ring

and the end face of side plate in precise contact with

one another.

Fig.3

In assembling this bearing, it must be handled with

good care to protect the seal lip from bending and flaw.

Side face

height

Where any of NTN roller followers was stub-

mounted, non-uniform load (bias load) could act

Fig.1 on the bearing, inversely affected by fitting

loose arising from further continued running.

Good care must be exercised of such fitting

loose, for stable running of the equipment.

B-164