Page 240 - needle bearings

P. 240

Cam followers stud type truck rollers

NTN

Bearing accuracy Fitting relations

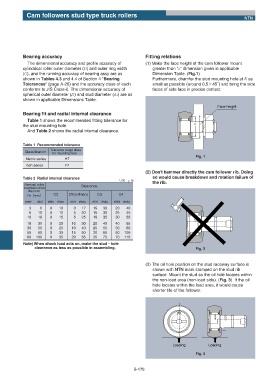

The dimensional accuracy and profile accuracy of (1) Make the face height at the cam follower mount

cylindrical roller outer diameter (D) and outer ring width greater than "e" dimension given in applicable

(C), and the running accuracy of bearing assy are as Dimension Table. (Fig.1)

shown in Tables 4.3 and 4.4 of Section 4 "Bearing Furthermore, chamfer the stud mounting hole at R as

Tolerances" (page A-26) and the accuracy class of each small as possible (around 0.5ʷ45˚) and bring the side

conforms to JIS Class-0. The dimensional accuracy of faces of side face in precise contact.

spherical outer diameter (D) and stud diameter (d1) are as

shown in applicable Dimensions Table.

Face height

Bearing fit and radial internal clearance

Table 1 shows the recommended fitting tolerance for

the stud mounting hole. e

And Table 2 shows the radial internal clearance.

Table 1 Recommended tolerance

Tolerance range class

Classification for mounting hole

Fig. 1

Metric series H7

Inch series F7

(2) Don't hammer directly the cam follower rib. Doing

Table 2 Radial internal clearance so would cause breakdown and rotation failure of

Unit : Жm

the rib.

Nominal roller Clearance

inscribed circle

diameter

Fwʢmmʣ C2 CN (ordinary) C3 C4

over incl. min max min max min max min max

3 6 0 10 3 17 15 30 20 40

6 10 0 12 5 20 15 30 25 45

10 18 0 15 5 25 15 35 30 55

18 30 0 20 10 30 20 40 40 65

30 50 0 25 10 40 25 55 50 80

50 80 0 30 15 50 30 65 60 100

80 100 0 35 20 55 35 75 70 115

Note) When shock load acts on, make the stud - hole

clearance as less as possible in assembling. Fig. 2

(3) The oil hole position on the stud raceway surface is

shown with NTN mark stamped on the stud rib

surface. Mount the stud so the oil hole locates within

the non-load area (non-load side). (Fig. 3) If the oil

hole locates within the load area, it would cause

shorter life of the follower.

Loading Loading

Fig. 3

B-178