Page 241 - needle bearings

P. 241

Cam followers stud type truck rollers

NTN

(4) Particularly where loose of the mounting screw is

forecast due to wide amplitude vibration during Lubrication and how to feed and replenish

running, the mounting methods as illustrated in Fig. 4 grease into the follower

are available. Lubrication

The cam follower type with synthetic rubber seal (with

tail code LL) and the full-complement roller type are pre-

filled up with lithium soap base grease so they can be

used in the operating temperature range of -25 to

+100˚C.

The type with cage and with no seal is not filled up with

grease. If a grease pre-filled type is needed, feel free to

contact NTN.

Further, NTN Bearings with Solid Drease using solid

lubricant of less leakage is also available on request. Feel

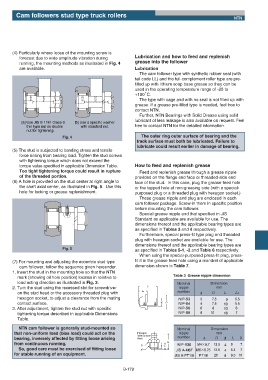

[a] Use JIS B 1181 Class-3 [b] Use a specific washer

thin type nut as double with standard nut. free to contact NTN for the detailed information.

nut for tightening.

Fig. 4 The outer ring outer surface of bearing and the

track surface must both be lubricated. Failure to

lubricate could result earlier in damage of bearing.

(5) The stud is subjected to bending stress and tensile

force arising from bearing load. Tighten the stud screws

with tightening torque which does not exceed the

torque value specified in applicable Dimension Table. How to feed and replenish grease

Too tight tightening torque could result in rupture Feed and replenish grease through a grease nipple

of the threaded portion. provided on the flange end face or threaded-side end

(6) A hole is provided on the stud center at right angle to face of the stud. In this case, plug the grease-feed hole

the shaft axial center, as illustrated in Fig. 5. Use this or the tapped hole at non-greasing side (with a special-

hole for locking or grease replenishment. purposed plug or a threaded plug with hexagon socket.)

These grease nipple and plug are enclosed in each

cam follower package. Screw-in them in specific position

before mounting the cam follower.

Special grease nipple and that specified in JIS

Standard as applicable are available for use. The

dimensions thereof and the applicable bearing types are

as specified in Tables 3 and 4 respectively.

Furthermore, special press-fit type plug and threaded

plug with hexagon socket are available for use. The

dimensions thereof and the applicable bearing types are

Fig. 5

as specified in Tables 5-1, -2 and Table 6 respectively.

When using the special-purposed press-fit plug, press-

(7) For mounting and adjusting the eccentric stud type fit it in the grease feed hole using a mandrel of applicable

cam follower, follow the sequence given hereunder. dimension shown in Table 7.

1. Insert the stud in the mounting hole so that the NTN

Table 3 Grease nipple dimension

mark (showing oil hole position) locates in relative to

load acting direction as illustrated in Fig. 3. Nominal Dimension

2. Turn the stud using the recessed slot for screwdriver L nipple mm

on the stud head or the accessory threaded plug with L1 number d D L L1

hexagon socket, to adjust a clearance from the mating NIP-B3 3 7.5 9 5.5

contact surface. d D NIP-B4 4 7.5 10 5.5

3. After adjustment, tighten the stud nut with specific NIP-B6 6 8 13 6

tightening torque described in applicable Dimensions NIP-B8 8 10 16 7

Table.

NTN cam follower is generally stud-mounted so Nominal Dimension

that non-uniform load (bias load) could act on the (Hexagon nipple mm

width across number

bearing, inversely affected by fitting loose arising flats) d H R L B

from continuous running. H NIP-X30 M4ʷ0.7 13.9 4 5 7

B r L

So, good care must be exercised of fitting loose d JIS A-M6F M6ʷ0.75 13.5 4 5.4 7

for stable running of an equipment. JIS A-PT1/8 PT1/8 20 8 9.5 10

B-179