Page 252 - needle bearings

P. 252

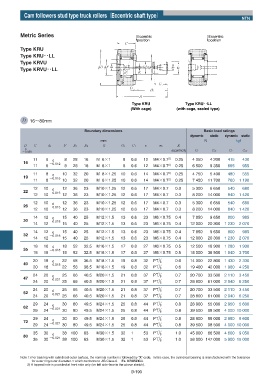

Cam followers stud type truck rollersʢEccentric shaft typeʣ

NTN

Metric Series Eccentric Eccentric

position position

Type KRU

Type KRUʝʝLL

Type KRVU

Type KRVUʝʝLL

Type KRU Type KRUʝLL

(With cage) (with cage, sealed type)

D 16ʙ80mm

Boundary dimensions Basic load ratings

dynamic static dynamic static

mm N kgf

D C d1 F B1 B2 G G1 C1 e m E

0 eccentricity

ʵ0.050 Cr Cor Cr Cor

11 6 0 8 28 16 M 6ʷ1 8 0.6 12 M4ʷ0.7 2) 0.25 4 050 4 200 415 430

16 ʵ0.012

11 6 8 28 16 M 6ʷ1 8 0.6 12 M4ʷ0.7 2) 0.25 6 500 9 350 665 955

11 8 0 10 32 20 M 8ʷ1.25 10 0.6 14 M4ʷ0.7 2) 0.25 4 750 5 400 480 555

19 ʵ0.015

11 8 10 32 20 M 8ʷ1.25 10 0.6 14 M4ʷ0.7 2) 0.25 7 450 11 700 760 1 190

12 10 0 12 36 23 M10ʷ1.25 12 0.6 17 M4ʷ0.7 0.3 5 300 6 650 540 680

22 ʵ0.015

12 10 12 36 23 M10ʷ1.25 12 0.6 17 M4ʷ0.7 0.3 8 200 14 000 840 1 420

12 10 0 12 36 23 M10ʷ1.25 12 0.6 17 M4ʷ0.7 0.3 5 300 6 650 540 680

26 ʵ0.015

12 10 12 36 23 M10ʷ1.25 12 0.6 17 M4ʷ0.7 0.3 8 200 14 000 840 1 420

14 12 0 15 40 25 M12ʷ1.5 13 0.6 23 M6ʷ0.75 0.4 7 850 9 650 800 985

30 ʵ0.018

14 12 15 40 25 M12ʷ1.5 13 0.6 23 M6ʷ0.75 0.4 12 000 20 300 1 230 2 070

14 12 0 15 40 25 M12ʷ1.5 13 0.6 23 M6ʷ0.75 0.4 7 850 9 650 800 985

32 ʵ0.018

14 12 15 40 25 M12ʷ1.5 13 0.6 23 M6ʷ0.75 0.4 12 000 20 300 1 230 2 070

18 16 0 18 52 32.5 M16ʷ1.5 17 0.8 27 M6ʷ0.75 0.5 12 500 18 900 1 280 1 930

35 ʵ0.018

18 16 18 52 32.5 M16ʷ1.5 17 0.8 27 M6ʷ0.75 0.5 18 000 36 500 1 840 3 700

20 18 0 22 58 36.5 M18ʷ1.5 19 0.8 32 PT!/8 0.6 14 000 22 800 1 430 2 330

40 ʵ0.018

20 18 22 58 36.5 M18ʷ1.5 19 0.8 32 PT!/8 0.6 19 400 42 000 1 980 4 250

24 20 0 25 66 40.5 M20ʷ1.5 21 0.8 37 PT!/8 0.7 20 700 33 500 2 110 3 450

47 ʵ0.021

24 20 25 66 40.5 M20ʷ1.5 21 0.8 37 PT!/8 0.7 28 800 61 000 2 940 6 250

24 20 0 25 66 40.5 M20ʷ1.5 21 0.8 37 PT!/8 0.7 20 700 33 500 2 110 3 450

52 ʵ0.021

24 20 25 66 40.5 M20ʷ1.5 21 0.8 37 PT!/8 0.7 28 800 61 000 2 940 6 250

29 24 0 30 80 49.5 M24ʷ1.5 25 0.8 44 PT!/8 0.8 28 900 55 000 2 950 5 600

62 ʵ0.021

29 24 30 80 49.5 M24ʷ1.5 25 0.8 44 PT!/8 0.8 39 500 98 500 4 000 10 000

29 24 0 30 80 49.5 M24ʷ1.5 25 0.8 44 PT!/8 0.8 28 900 55 000 2 950 5 600

72 ʵ0.021

29 24 30 80 49.5 M24ʷ1.5 25 0.8 44 PT!/8 0.8 39 500 98 500 4 000 10 000

35 30 0 38 100 63 M30ʷ1.5 32 1 53 PT!/8 1.0 45 000 88 500 4 600 9 050

80 ʵ0.021

35 30 38 100 63 M30ʷ1.5 32 1 53 PT!/8 1.0 58 000 147 000 5 900 15 000

Note 1) For bearing with cylindrical outer surface, the nominal number is followed by “X” code. In this case, the cylindrical bearing is manufactured with the tolerance

for outer ring outer diameter D which conforms to JIS Class-0. Ex. KRU52XLL

2) A tapped hole is provided at front side only (on left side-face in the above sketch).

B-190