Page 95 - needle bearings

P. 95

Drawn cup needle roller bearings

NTN

Bearing Fits Bearing installation

It is common that drawn cup needle bearing is press- Any drawn cup needle roller bearings must be press-

fitted in a housing by shrinkage fit so post press-fit fitted in the housing in specific position by holding a

inscribed circle diameter (Fw) comes to ISO Tolerance specific jig in perfect contact with the mark-stamped side

Rang Class F8. The post press-fit inscribed circle face of the bearing, without fail.

diameter (Fw) depends on the housing material and Further, hammering directly the bearing ring in

rigidity. It is therefore desirable to decide the interference installing (press-fitting) is not allowed absolutely. In

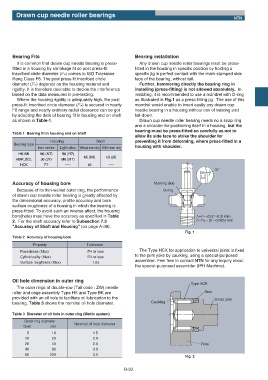

based on the data measured in pre-testing. installing, it is recommended to use a mandrel with O-ring

Where the housing rigidity is adequately high, the post as illustrated in Fig.1 as a press-fitting jig. The use of this

press-fit inscribed circle diameter (Fw) is secured in nearly mandrel would enable to insert easily any drawn cup

F8 range and nearly ordinary radial clearance can be got needle bearing in a housing without risk of twisting and

by adopting the data of bearing fit in housing and on shaft fall-down.

as shown in Table-1. Drawn cup needle roller bearing needs no a snap ring

and a shoulder for positioning itself in a housing, but the

bearing must be press-fitted so carefully as not to

Table 1 Bearing fit in housing and on shaft

allow its side face to strike the shoulder for

Housing Shaft preventing it from deforming, where press-fitted in a

Bearing type

Iron series Light alloy Without inner ring With inner ring housing with shoulder.

HK,BK N6 (N7) R6 (R7)

h5 (h6) k5 (j6)

HMK,DCL J6 (J7) M6 (M7)

HCK F7 –––– k6 ––––

15˚

Accuracy of housing bore Marking side

Because of its thin-walled outer ring, the performance O-ring A

of drawn cup needle roller bearing is greatly affected by

the dimensional accuracy, profile accuracy and bore

surface roughness of a housing in which the bearing is

B

press-fitted. To avoid such an inverse affect, the housing A

bore(hole) must have the accuracy as specified in Table A Dʵ(0.2ʙ0.3) mm

2. For the shaft accuracy refer to Subsection 7.3 B=Fwʵ(0ʙ0.025) mm

"Accuracy of Shaft and Housing" (on page A-39).

Fig. 1

Table 2 Accuracy of housing bore

Property Tolerance

Roundness (Max) IT4 or less The Type HCK for application to universal joints is fixed

to the joint yoke by caulking, using a special-purposed

Cylindricality (Max) IT4 or less

assembler. Feel free to contact NTN for any inquiry about

Surface roughness (Max) 1.6a

the special-purposed assembler (IPH Machine).

Oil hole dimension in outer ring

Type HCK

The outer rings of double-row (Tail code : ZW) needle

roller and cage assembly Type HK and Type BK are Seal

provided with an oil hole to facilitate oil lubrication to the Cross joint

bearing. Table 3 shows the nominal oil hole diameter. Caulking

Table 3 Diameter of oil hole in outer ring (Metric system)

Outer ring diameter

Nominal oil hole diameter

Over incl.

5 10 1.5

10 20 2.0

20 40 2.5 Yoke

40 80 3.0

80 200 3.5

Fig. 2

B-33