Page 178 - domce

P. 178

9 EXTERNAL SELF ALIGNING BALL BEARING UNITS

Installing the bearing unit to the shaft the bearing unit is not subjected to axial loads. Then fit

the eccentric collar to the bearing unit.

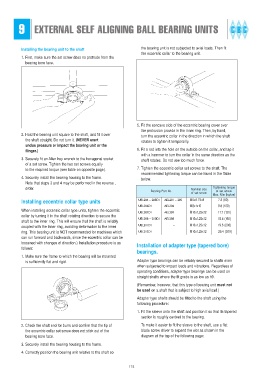

1. First, make sure the set screw does no protrude from the

bearing bore face.

5. Fit the concave side of the eccentric bearing cover over

the protrusion provide in the inner ring. Then, by hand,

2. Hold the bearing unit square to the shaft, and fit it over turn the eccentric collar in the direction in which the shaft

the shaft straight. Do not turn it. (NEVER exert rotates to tighten it temporarily.

undue pressure or impact the bearing unit or the

flinger.) 6. Fit a rod into the hole on the outside on the collar, and tap it

with a hammer to turn the collar in the same direction as the

3. Securely fit an Allen key wrench to the hexagonal socket shaft rotates. Do not use too much force.

of a set screw. Tighten the two set screws equally

to the required torque (see table on opposite page). 7. Tighten the eccentric collar set screws to the shaft. The

recommended tightening torque can be found in the Table

4. Securely install the bearing housing to the frame. below.

Note that steps 3 and 4 may be performed in the reverse ,

order. N o e z i s l a n i m g n i n e t h g i T e u q r o t

B g n i r a e P t r a N . o f o e r c s t e s w

f o e r c s t e s w

M . x a m / N c / g k ( ) m

Installing eccentric collar type units U 4 0 2 L E – 5 0 2 D 1 A 1 0 2 L E – 5 0 2 M 8 x 5 7 . 0 x 6 8 . 7 ) 0 8 (

U 6 0 2 L E D 1 A 6 0 2 L E M 0 1 x 1 x 8 8 . 9 ) 0 0 1 (

When installing eccentric collar type units, tighten the eccentric

U 7 0 2 L E D 1 A 7 0 2 L E M 2 1 x 5 2 . 1 x 0 1 7 . 1 1 ) 0 2 1 (

collar by turning it in the shaft rotating direction to secure the

U 8 0 2 L E – 0 1 2 D 1 A 8 0 2 L E M 2 1 x 5 2 . 1 x 0 1 6 . 5 1 ) 0 6 1 (

shaft to the inner ring. This will ensure that the shaft is reliably

coupled with the inner ring, avoiding deformation to the inner U 1 1 2 L E D 1 – M 2 1 x 5 2 . 1 x 0 1 6 . 9 1 ) 0 0 2 (

ring. This bearing unit is NOT recommended for machines which U 2 1 2 L E D 1 – M 2 1 x 5 2 . 1 x 0 1 4 . 9 2 ) 0 0 3 (

can run forward and backwards, since the eccentric collar can be

loosened with changes of direction.) Installation procedure is as Installation of adapter type (tapered bore)

follows:

bearings.

1. Make sure the frame to which the bearing will be mounted

is sufficiently flat and rigid. Adapter type bearings can be reliably secured to shafts even

when subjected to impact loads and vibrations. Regardless of

operating conditions, adapter type bearings can be used on

straight shafts where the fit grade is as low as h9.

(Remember, however, that this type of bearing unit must not

be used on a shaft that is subject to high axial load.)

Adapter type shafts should be fitted to the shaft using the

following procedure:

1. Fit the sleeve onto the shaft and position it so that its tapered

section is roughly centred to the bearing.

2. Check the shaft end for burrs and confirm that the tip of To make it easier to fit the sleeve to the shaft, use a flat

the eccentric collar set screw does not stick out of the blade screw driver to expand the slot as shown in the

bearing bore face. diagram at the top of the following page:

3. Securely install the bearing housing to the frame.

4. Correctly position the bearing unit relative to the shaft so

174