Page 189 - domce

P. 189

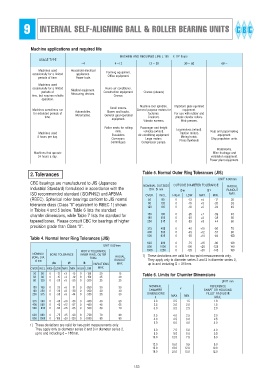

9 INTERNAL SELF-ALIGNING BALL & ROLLER BEARING UNITS

Machine applications and required life

M A C N I H E A N D R E Q R I U E D F I L E L 01 h X 0 1 3 s r u o h

U S A G E T Y P E

~ 4 4 ~ 1 2 1 2 ~ 3 0 3 0 ~ 6 0 6 0 ~

M s e n i h c a d e s u H d l o h e s u o l a c i r t c e l e g n i m r a F p i u q e m . t n e

r o f y l l a n o i s s a c o d e t i m i l a . s e c n a i l p p a

s d o i r e p m i t f o . e P o w s l o o t r e e c i f f O p i u q e m . t n e

M s e n i h c a d e s u

r o f y l l a n o i s s a c o d e t i m i l a H o m e r i a . r e n o i t i d n o c

s d o i r e p f o M p i u q e l a c i d e m . t n e C n o i t c u r t s n o p i u q e m . t n e s e n a r C ) e v a e h s (

m i t , e s e r i u q e r t u b e l b a i l e r M g n i r u s a e . s e c i v e d . s e n a r C

. n o i t a r e p o

M e n i h c a . s e l d n i p s l o o t m I t n a t r o p d e t a r e p o - r a e g

S m l l a m . s r o t o

M s e n i h c a o s m m i t e s e n u r A o t u m . s e l i b o B s e s u d n a . s k c u r t G e s o p r u p l a r e n e m r o f s r o t o p i u q e m . t n e

r o f d e d n e t x e s d o i r e p f o M . s e l c y c r o t o G d e t a r e p o - r a e g l a r e n e . s e i r o t c a f r o F e s u h t i w r e b b u r d n a

m i t . e . s r e h s u r C c i t s a l p . s r e l l o r r a d n a l c

p i u q e m . t n e

r o t a r b i V . s n e e r c s W b e . s e s s e r p

R r e l l o g n i l l o r r o f s k c e n P r e g n e s s a d n a t h g i e r f o c o L m s e v i t o w ( . ) l e e h

. s l l i m s e l c i h e v w ( . ) l e e h P p l u d n a m r e p a p g n i k a

M s e n i h c a d e s u n o i t c a r T m . s r o t o

8 s r u o h r e p . y a d . s r o t a l a c s E g n o i t i d n o c - r i A p i u q e m . t n e g n i n i M . s t s i o h p i u q e m . t n e

C . s r o y e v n o e g r a L m . s r o t o S p i h n o i s l u p o r p . s t i n u

C e . s e g u f i r t m C o m r o s s e r p u p m . s p y l f s s e r P w s l e e h

W w r e t a . s k r o

M t a h t s e n i h c a e t a r e p o e n i M e g a n i a r d d n a

4 2 s r u o h a . y a d n o i t a l i t n e v p i u q e m . t n e

P o w r e t n a l p p i u q e m . t n e

2. Tolerances Table 5. Normal Outer Ring Tolerances (JIS)

U T I N 1 0 0 . 0 m m

CBC bearings are manufactured to JIS (Japanese

N O N I M A L O U T D I S E O U T D I S E A I D M T E E R T O L E R A N C E R A A I D L

Industrial Standard) formulated in accordance with the . A I D D m m D m D ) 1 R U N O U T

ISO recommended standard (ISO/R492) and AFBMA O V E . R N I C . L G I H H L O W M A . X . N I M M A . X

(RBEC). Spherical roller bearings conform to JIS normal 0 5 0 8 0 3 1 - 4 + 7 1 - 5 2

0 8 0 2 1 0 5 1 - 5 + 0 2 - 5 3

tolerance class (Class “0” equivalent to RBEC 1) shown

0 2 1 0 5 1 0 8 1 - 6 + 4 2 - 0 4

in Tables 4 and 5 below. Table 6 lists the standard

0 5 1 0 8 1 0 5 2 - 7 + 2 3 - 5 4

chamfer dimensions, while Table 7 lists the standard for

0 8 1 0 5 2 0 0 3 - 8 + 8 3 - 0 5

tapered bores. Please consult CBC for bearings of higher 0 5 2 5 1 3 0 5 3 - 9 + 4 4 - 0 6

precision grade than Class “0”.

5 1 3 0 0 4 0 0 4 - 0 1 + 0 5 - 0 7

0 0 4 0 0 5 0 5 4 - 2 1 + 7 5 - 0 8

0 0 5 0 3 6 0 0 5 - 4 1 + 4 6 - 0 0 1

Table 4. Normal Inner Ring Tolerances (JIS)

0 3 6 0 0 8 0 5 7 - 5 1 + 0 9 - 0 2 1

U T I N 1 0 0 . 0 m m 0 0 8 0 0 0 1 0 0 0 1 - 0 2 + 0 2 1 - 0 4 1

0 0 0 1 0 5 2 1 0 5 2 1 - 0 2 + 5 4 1 - 0 6 1

W D I T H T O E L R A N C E

N O N I M A L B O R E T O E L R A N C E N I N E R N I R , G O U T E R

B O R E . A I D N I R G R A A I D L 1) These deviations are valid for two-point measurements only.

d m m R U N O U T They apply only to diameter series 2 and 3 in diameter series 2,

d m d ) 1 B V A A I R O I T N S M A . X up to and including D = 315mm.

O V E . R NI C . L H G I H OL W M A . X M . N I G I H H OL W M A . X

0 3 0 5 0 2 1 - 3 + 5 1 - 0 0 2 1 - 0 2 5 1 Table 6. Limits for Chamfer Dimensions

0 5 0 8 0 5 1 - 4 + 9 1 - 0 0 5 1 - 5 2 0 2

0 8 0 2 1 0 0 2 - 5 + 5 2 - 0 0 0 2 - 5 2 5 2 U T I N m m

N O N I M A L R F E E R E N C E

0 2 1 0 8 1 0 5 2 - 6 + 1 3 - 0 0 5 2 - 0 3 0 3 r

0 8 1 0 5 2 0 0 3 - 8 + 8 3 - 0 0 0 3 - 0 3 0 4 C H A M F E R S H A T F O R H O U N I S G

0 5 2 5 1 3 0 5 3 - 9 + 4 4 - 0 0 5 3 - 5 3 0 5 M I D E N O I S N S M A . X . N I M L L I F T E R A U I D S R

r M A . X

5 1 3 0 0 4 0 0 4 - 0 1 + 0 5 - 0 0 0 4 - 0 4 0 6 0 . 2 5 . 2 5 . 1 0 . 1

0 0 4 0 0 5 0 5 4 - 2 1 + 7 5 - 0 0 5 4 - 5 4 5 6 5 . 2 0 . 3 0 . 2 5 . 1

0 0 5 0 3 6 0 0 5 - 5 1 + 5 6 - 0 0 0 5 - 0 5 0 7 0 . 3 5 . 3 5 . 2 0 . 2

0 3 6 0 0 8 0 5 7 - 5 1 + 0 9 - 0 0 5 7 - 0 7 0 8 5 . 3 0 . 4 5 . 2 0 . 2

0 0 8 0 0 0 1 0 0 0 1 - 0 2 + 0 2 1 - 0 0 0 0 1 - 0 9 0 9 0 . 4 5 . 4 0 . 3 5 . 2

0 . 5 0 . 6 0 . 4 0 . 3

1) These deviations are valid for two-point measurements only.

They apply only to diameter series 2 and 3 in diameter series 2, 0 . 6 5 . 7 0 . 5 0 . 4

up to and including d = 180mm. 0 . 8 0 . 9 0 . 6 0 . 5

0 . 0 1 5 . 2 1 5 . 7 0 . 6

0 . 2 1 0 . 5 1 5 . 9 0 . 8

0 . 5 1 0 . 8 1 0 . 2 1 0 . 0 1

0 . 8 1 0 . 1 2 0 . 5 1 0 . 2 1

185