Page 193 - domce

P. 193

9 INTERNAL SELF-ALIGNING BALL & ROLLER BEARING UNITS

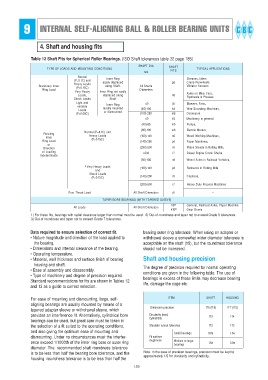

4. Shaft and housing fits

Table 12 Shaft Fits for Spherical Roller Bearings. (ISO Shaft tolerances table 22 page 185)

S H A F T A I D S H A F T

T Y P E O F L O A D S A N D M O U N N I T G C O N O I T I D N S T Y C I P A L A P P C I L A O I T N S

m m T I F S

N m r o l a

P ( ) C 1 . 0 = d n a r e n n I g n i R S s r e l d I , s e v a e h

H y v a e s d a o L y l i s a e d e c a l p s i d 6 g e n a r C R n u w s l e e h

r e n n I y r a n o i t a t S P ( 5 1 . 0 > ) C g n o l a S . t f a h l l A S s f t a h r o t a r b i V S s n e e r c

g n i R d a o L a i D m s r e t e

V y r e H y v a e r e n n I g n i R t o n y l i s a e A s e l x n o e n i M C , s r a

, s d a o L d e c a l p s i d g n o l a 6 h

S k c o h s d a o L S t f a h y l F w n i s l e e h s e s s e r P

t h g i L d n a r e n n I g n i R 0 4 6 j o l B w , s r e , s n a F

e l b a i r a v

s d a o L y l i d a e r m d e t n u o 0 0 1 - ) 0 4 ( 6 k e r i W g n i d n a r t S M , s e n i h c a

P ( 8 0 . 0 < ) C r o s i d m d e t n u o 0 0 2 - ) 0 0 1 ( m 6 C s r o y e v n o

0 4 5 k M n i y r e n i h c a l a r e n e g

5 6 - ) 0 4 ( m 5 P u m , s p

0 0 1 - ) 5 6 ( m 6 c i r t c e l E M , s r o t o

N m r o P ( l a ) C 1 . 0 = d n a

R g n i t a t o H y v a e s d a o L 0 4 1 - ) 0 0 1 ( 6 n W d o o W g n i k r o M , s e n i h c a

r e n n I

g n i R d a o L P ( 5 1 . 0 > ) C 0 8 2 - ) 0 4 1 ( 6 p P r e p a M , s e n i h c a

r o

n o i t c e r i D 0 0 5 - ) 0 8 2 ( 6 r n o i n i P n i s d n a t S R g n i l l o , s l l i M

f o g n i d a o L 0 0 5 > 7 r l e s e i D e n i g n E k n a r C S s t f a h

e t a n i m r e t e d n I

0 0 1 - ) 0 5 ( 6 n W l e e h A n i s e l x R d a o r l i a V , s e l c i h e

) 1 V y r e H y v a e s d a o L 0 4 1 - ) 0 0 1 ( 6 p R n i s k c e n l l o R g n i l l o s l l i M

d n a

S k c o h s d a o L

P ( 5 1 . 0 > ) C 0 0 2 - ) 0 4 1 ( 6 r , s r e h s u r C

0 0 5 - ) 0 0 2 ( 7 r H y v a e D y t u s s e c o r P M s e n i h c a

P e r u T t s u r h d a o L l l A S t f a h a i D m s r e t e 6 j –

T A P E R B O R E B E A N I R G S ( W T I H T A P E R E D S L E E V ) E

9 h ) 2 G , l a r e n e R d a o r l i a A , s e l x P r e p a M e n i h c a

s d a o L l l A l l A S t f a h a i D m s r e t e

0 1 h ) 3 G r a e B s e x o

1) For these fits, bearings with radial clearance larger than normal must be used. 2) Out-of-roundness and taper not to exceed Grade 5 tolerances.

3) Out-of roundness and taper not to exceed Grade 7 tolerances.

Data required to ensure selection of correct fit. bearing outer ring tolerance. When using an adapter or

• Nature magnitude and direction of the load applied to withdrawal sleeve a somewhat wider diameter tolerance is

the bearing. acceptable on the shaft (h9), but the roundness tolerance

• Dimensions and internal clearance of the bearing. should not be increased.

• Operating temperature.

• Material, wall thickness and surface finish of bearing Shaft and housing precision

housing and shaft. The degree of precision required for normal operating

• Ease of assembly and disassembly. conditions are given in the following table. The use of

• Type of machinery and degree of precision required. bearings in excess of these limits may decrease bearing

Standard recommendations for fits are shown in Tables 12 life, damage the cage etc.

and 13 as a guide to correct selection.

For ease of mounting and dismounting, large. self- T I E M S H A T F H O U N I S G

aligning bearings are usually mounted by means of a

m i D n o i s n e n o i s i c e r p ) 5 T I ( 6 T I 7 T I ) 5 T I (

tapered adapter sleeve or withdrawal sleeve, which

provides an interference fit. Alternatively, cylindrical bore m ( y t i r a l u c r i C ) x a 3 T I 4 T I

y t i c i r d n i l y C

bearings can be used, but great care must be taken in

the selection of a fit suited to the operating conditions, S e c n a r e l o t t u o n u r r e d l u o h 3 T I 3 T I

and also giving the optimum ease of mounting and

S m s g n i r a e b l l a a 8 . 0 a 6 . 1

dismounting. Under no circumstances must the interfer- e c a f r u s t i F

s s e n h g u o r M u i d e m e g r a l o t

ence exceed 1/1000th of the inner ring bore or outer ring a 6 . 1 a 2 . 3

s g n i r a e b

diameter. The recommended shaft roundness tolerance

is to be less than half the bearing bore tolerance, and the Note: In the case of precision bearings, precision must be kept to

approximately 1/2 for circularity and cylindricity.

housing roundness tolerance is to be less than half the

189