Page 195 - domce

P. 195

9 INTERNAL SELF-ALIGNING BALL & ROLLER BEARING UNITS

5. Handling bearings

Dismounting Bearings

Prior to dismounting a bearing which is to be re-used,

careful consideration should be given to the shaft and

housing fits, i.e. which is “tight” and which is “loose”. In

most applications the inner ring is an interference fit on

the shaft and the outer ring is a clearance fit in the

housing, in which case it is normal practice to first

remove the housing from the bearing outer ring and then

to remove the bearing from the shaft. When this opera-

tion is performed, pressure must be applied only directly

Clamping jig

to the inner ring, (or whichever is the “tight” fit). This will Fig. 2

prevent brinnelling of the raceways which will occur if

pressure or impact is applied to the “tight” ring from the

Hydraulic dismounting methods

“loose” ring via the rolling elements.

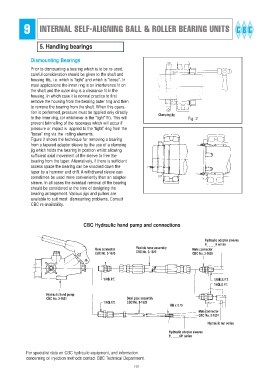

Figure 2 shows the technique for removing a bearing

from a tapered adapter sleeve by the use of a clamping

jig which holds the bearing in position whilst allowing

sufficient axial movement of the sleeve to free the

bearing from the taper. Alternatively, if there is sufficient

access space the bearing can be knocked down the

taper by a hammer and drift. A withdrawal sleeve can

sometimes be used more conveniently than an adapter

sleeve. In all cases the eventual removal of the bearing

should be considered at the time of designing the

Fig. 3 Fig. 4

bearing arrangement. Various jigs and pullers are

available to suit most dismounting problems. Consult

CBC re-availability.

CBC Hydraulic hand pump and connections

Hydraulic adapter sleeves

H_ _ _ _H series

Flexible hose assembly

Male connector Male connector

CBC No. 3-1630 CBC No. 3-1622 CBC No. 3-1629

1/4Ó N.P.T. 1/8Ó B.S.P.T.

1/4Ó B.S.P.T.

Hydraulic hand pump

CBC No. 3-1621 Steel pipe assembly

1/4Ó N.P.T. CBC No. 3-1623

M6 x 0.75

Male connector

CBC No. 3-1624

Hydraulic nut series

Hydraulic adapter sleeves

H_ _ _ _OH series

For specialist data on CBC hydraulic equipment, and information

concerning oil injection methods contact CBC Technical Department.

191