Page 196 - domce

P. 196

9 INTERNAL SELF-ALIGNING BALL & ROLLER BEARING UNITS

5. Handling bearings

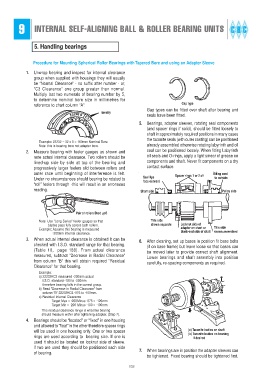

Procedure for Mounting Spherical Roller Bearings with Tapered Bore and using an Adapter Sleeve

1. Unwrap bearing and inspect for internal clearance

group when supplied with housings they will usually

be “Normal Clearance” - no suffix after number - or,

“C3 Clearance” one group greater than normal. or

Multiply last two numerals of bearing number by 5,

to determine nominal bore size in millimetres for

reference to chart column “A”. Gap type

Gap types can be fitted over shaft after bearing and

Identify

seals have been fitted.

5. Bearings, adapter sleeves, rotating seal components

(and spacer rings if solid), should be fitted loosely to

shaft in approximately required positions in many cases

the taconite seals (with outer casting) can be positioned

Example: 22232 – 32 x 5 = 160mm Nominal Bore

Note: this is bearing bore not adapter bore. already assembled otherwise rotating labyrinth and oil

2. Measure bearing with feeler gauges as shown and seal can be positioned loosely. When fitting Labyrinth

note actual internal clearance. Two rollers should be oil seals and O-rings, apply a light smear of grease on

lined-up side by side at top of the bearing and components and shaft. Never fit components on a dry

progressively larger feelers slid between rollers and contact surface.

outer race until beginning of interference is felt. Spacer rings 1 or 2 off ÒOÓ ring cord

Under no circumstances should bearing be rotated to Seal lips to outside

face outward

“roll” feelers through -this will result in an erroneous

reading. Short side Pulley side

Pair of rollers Òlined upÓ

Note: Use “Long Series” feeler gauges so that This side

blades pass fully across both rollers. shown separate Locknut side of

Example: Assume this bearing is measured adapter on short or This side

. blank-end side of shaft shown assembled

200mm internal clearance.

3. When actual internal clearance is obtained it can be

6. After cleaning, set up bases in position fit base bolts

checked with I.S.O. standard range for that bearing.

(if on base frame) but leave loose so that bases can

(Table 10, page 188). From actual clearance

be moved later to provide correct shaft alignment.

measured, subtract “Decrease in Radial Clearance”

Lower bearings and shaft assembly into position

from column “B” this will obtain required “Residual

carefully, re-spacing components as required.

Clearance” for that bearing.

Example:

.

a) 22232KC3 measured 200mm actual

.

.

I.S.O. standard 180 to 230mm

therefore bearing falls in the correct group.

b) Read “Decrease in Radial Clearance” from

.

.

column “B” 22232KC3 075 to 100mm.

c) Residual Internal Clearance

.

.

.

Target Max = 200Minus 075 = 125mm

.

.

.

Target Min = 200 Minus 100 = 100mm

This residual clearance range is what the bearing

should measure within after tightening adapter, (Step 7).

4. Bearings should be “located” or “fixed” in one housing

and allowed to “float” in the other therefore spacer rings

will be used in one housing only. One or two spacer (a) Taconite bodies on shaft

(b) Taconite bodies on housing

rings are used according to bearing size. If one is if desired

used it should be located on locknut side of sleeve.

If two are used they should be positioned each side

of bearing. 7. When bearings are in position the adapter sleeves can

be tightened. Fixed bearing should be tightened first,

192