Page 314 - needle bearings

P. 314

Linear roller bearings

NTN

Linear Roller Bearings

This roller bearing with cylindrical rollers having the

function capable of circulating within the raceway block Requirements and tolerances for raceway

ensures smooth infinite linear motion on a flat surface. surface and mounting surface

The cylindrical rollers are retained and guided by the Table 2 shows the requirements and tolerances for the

cage and the ribs of the raceway block. raceway surface, on which linear roller bearing rolls, and

The cage is of such a construction as not allow the bearing mounting surface. Where adhesion of a hard

adjacent rollers to contact with one another. Hence, the foreign matter to the raceway surface is forecast, the

friction coefficient is low. raceway surface must be protected with a proper

protective cover.

The reference surface for mounting is the back face

and opposite face to NTN mark.

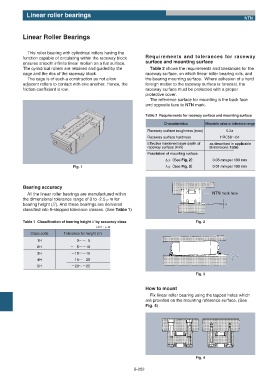

Table 2 Requirements for raceway surface and mounting surface

Characteristics Allowable value or tolerance range

Raceway surface roughness (max) 0.2a

Raceway surface hardness HRC58ʙ64

Effective hardened layer depth of as described in applicable

raceway surface (min) Dimensions Table

Parallelism of mounting surface

ɹɹɹɹɹ∆ x ʢSee Fig. 2ʣ 0.05 mm per 100 mm

Fig. 1 ɹɹɹɹɹ∆ yʢSee Fig. 3ʣ 0.01 mm per 100 mm

Bearing accuracy

All the linear roller bearings are manufactured within NTN mark here

the dimensional tolerance range of 0 to -2.5Жm for

bearing height (H). And these bearings are delivered

classified into 5-stepped tolerance classes. (See Table 1)

Table 1 Classification of bearing height H by accuracy class Fig. 2

Unit : Жm

Class code Tolerance for height (H)

1H 0ʙʵ 5

2H ʵ 5ʙʵ10

3H ʵ10ʙʵ15

4H ʵ15ʙʵ20

5H ʵ20ʙʵ25

Fig. 3

How to mount

Fix linear roller bearing using the tapped holes which

are provided on the mounting reference surface. (See

Fig. 4)

Fig. 4

B-252