Page 310 - needle bearings

P. 310

Linear flat rollers

NTN

Linear Flat Rollers

Linear Flat Rollers How to mount

This bearing type composed of a needle roller and flat Theoretically the linear flat roller bearing moves by 1/2

cage assembly (needle rollers are configured in the flat of table moving stroke in same direction as the table

cage) ensures smooth reciprocating motion with less moving direction. The relationship of bed length (L) -

friction coefficient. stroke (S) - cage length (L1) can be expressed in formula

(1). (Fig. 2)

Types

LʹS 2 L ʜʜʜʜʜʜʜʜʜʜʜʜʜʜʜʜʢ1ʣ

For Type FF, the polyamide resin cage has a dovetail

joint groove on its both ends so that several cages can be

jointed together into one unit.

For Type FFʝʝZW, two rows of needle rollers are

L1 S

configured in the cage and the cage has an elastic joint

on its center so as to enable to bend two rows of flat

rollers to any optional angle at the elastic joint by heating

them in oil of 70 to 90˚C. The two roller rows bent to any

optional angle can hold the bent shape unchanged, even

under normal operating temperature, by being cooled S/2

L

down for several seconds, with the bending angle held

unchanged.

Fig. 2

For Type BF, the cage is press-formed from steel plate

and the standard length of the bearing unit is 1000 mm.

For Type RF, the cage is of polyamide resin and the The linear flat roller bearing results in moving deviation

standard length of the bearing unit is 705 mm. The both due to profile deviation of raceway surface, uneven load

are unavailable for cage to cage inter-jointing, but a or vibration. Therefore, the table or the bed must be

bearing unit of any desired length is offerable upon equipped with a stopper at its end portion to prevent over-

request. Feel free to contact NTN for the detailed run of the flat roller bearing. (Fig. 5)

information. Figs. 3 and 4 illustrate application examples of the

linear flat roller bearing unit.

Needle roller tolerance

The needle rollers contained in the flat roller cage are

manufactured within the dimensional tolerance range of 0

to -2 mm against the nominal diameter (Dw).

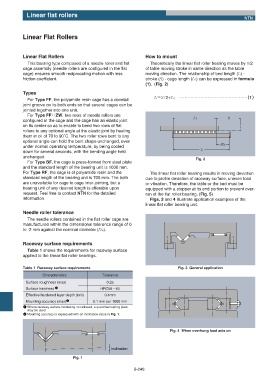

Raceway surface requirements

Table 1 shows the requirements for raceway surface

applied to the linear flat roller bearings.

Table 1 Raceway surface requirements Fig. 3 General application

Characteristics Tolerance

Surface roughness (max) 0.2a

Surface hardness 1 HRC58ʙ64

Effective hardened layer depth (min) 0.4mm

Mounting accuracy (max) 2 0.1 mm per 1000 mm

1 Where raceway surface hardening not allowed, a quenched spring plate

ɹ may be used.

2 Mounting accuracy is expressed with an inclination value in Fig. 1.

Fig. 4 When overhung load acts on

Inclination

Fig. 1

B-248