Page 339 - needle bearings

P. 339

Appendix

NTN

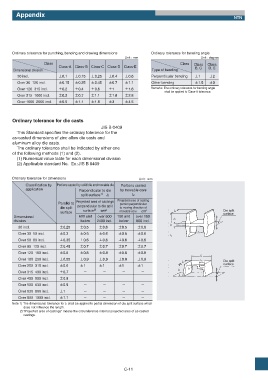

Ordinary tolerance for punching, bending and drawing dimensions Ordinary tolerance for bending angle

Unit : mm Unit : degree

Class Class Class Class

Class-A Class-B Class-C Class-D Class-E B, C D, E

Dimensional division Type of bending

30 incl. ʶ0.1 ʶ0.15 ʶ0.25 ʶ0.4 ʶ0.6 Perpendicular bending ʶ1 ʶ2

Over 30 120 incl. ʶ0.15 ʶ0.25 ʶ0.45 ʶ0.7 ʶ1.1 Other bending ʶ1.5 ʶ3

Over 120 315 incl. ʶ0.2 ʶ0.4 ʶ0.6 ʶ1 ʶ1.6 Remarks: The ordinary tolerance for bending angle

shall be applied to Class-A tolerance.

Over 315 1000 incl. ʶ0.3 ʶ0.7 ʶ1.1 ʶ1.8 ʶ2.8

Over 1000 2000 incl. ʶ0.5 ʶ1.1 ʶ1.8 ʶ3 ʶ4.5

Ordinary tolerance for die casts

JIS B 0409

This Standard specifies the ordinary tolerance for the

as-casted dimensions of zinc allow die casts and

aluminum alloy die casts.

The ordinary tolerance shall be indicated by either one

of the following methods (1) and (2).

(1) Numerical value table for each dimensional division

(2) Applicable standard No. Ex.:JIS B 0409

Ordinary tolerance for dimensions Unit : mm

Classification by Portions casted by solid die and movable die Portions casted

application Perpendicular to die by movable core

split surface ʣ l2 l2

Projected area of castings Projected area of casting

Parallel to portion perpendicular

perpendicular to die split

die split to moving direction of

surface ʣ cm 2 movable core cm 2 Die split

surface l1 surface

Dimensional 600 and over 600 150 and over 150

division below 2400 incl. below 600 incl. l2

l2

30 incl. ʶ0.25 ʶ0.5 ʶ0.6 ʶ0.5 ʶ0.6

Over 30 50 incl. ʶ0.3 ʶ0.5 ʶ0.6 ʶ0.5 ʶ0.6 l1

Over 50 80 incl. ʶ0.35 ʶ0.6 ʶ0.6 ʶ0.6 ʶ0.6

Over 80 120 incl. ʶ0.45 ʶ0.7 ʶ0.7 ʶ0.7 ʶ0.7

Over 120 180 incl. ʶ0.5 ʶ0.8 ʶ0.8 ʶ0.8 ʶ0.8

l1

Over 180 250 incl. ʶ0.55 ʶ0.9 ʶ0.9 ʶ0.9 ʶ0.9

l3 Die split

l1

Over 250 315 incl. ʶ0.6 ʶ1 ʶ1 ʶ1 ʶ1 surface

l2

l2

Over 315 400 incl. ʶ0.7 ɹʵ ɹʵ ɹʵ ɹʵ

Over 400 500 incl. ʶ0.8 ɹʵ ɹʵ ɹʵ ɹʵ

Over 500 630 incl. ʶ0.9 ɹʵ ɹʵ ɹʵ ɹʵ

Over 630 800 incl. ʶ1 ɹʵ ɹʵ ɹʵ ɹʵ

Over 800 1000 incl. ʶ1.1 ɹʵ ɹʵ ɹʵ ɹʵ

Note 1) The dimensional tolerance for l1 shall be applied to partial dimension of die split surface which

does not influence the length.

2) “Projected area of castings” means the circumference internal projected area of as-casted

castings.

C-11