Page 307 - needle bearings

P. 307

Linear ball bearings, stroke type

NTN

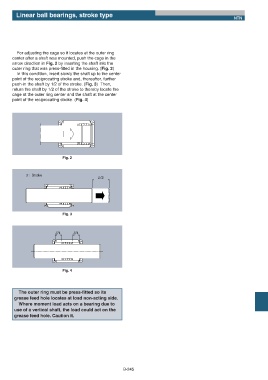

For adjusting the cage so it locates at the outer ring

center after a shaft was mounted, push the cage in the

arrow direction in Fig. 2 by inserting the shaft into the

outer ring that was press-fitted in the housing. (Fig. 2)

In this condition, insert slowly the shaft up to the center

point of the reciprocating stroke and, thereafter, further

push-in the shaft by 1/2 of the stroke. (Fig. 3) Then,

return the shaft by 1/2 of the stroke to thereby locate the

cage at the outer ring center and the shaft at the center

point of the reciprocating stroke. (Fig. 4)

Fig. 2

SɿStroke

S 2

Fig. 3

S 4 S 4

Fig. 4

The outer ring must be press-fitted so its

grease feed hole locates at load non-acting side.

Where moment load acts on a bearing due to

use of a vertical shaft, the load could act on the

grease feed hole. Caution it.

B-245