Page 49 - needle bearings

P. 49

Sealing Devices

NTN

9. Sealing Devices

lubricating condition, environmental condition, economical

9.1 Non-contact seal and contact seal merit, etc., so that bearing running is not inversely

The purpose of using a seal is to prevent a lubricant affected by the sealing device.

held in a bearing from leaking outside the bearing and to The bearing seals are mainly classified into non-contact

prevent powder, water content, etc. from invading into the seal, contact seal, etc. as shown in Tables 9.1 and 9.2,

bearing from outside. which must then be selected correctly according to each

It is very important to design a sealing device with good application,under full consideration of the characteristics

care, under full consideration of the operating conditions, of each sealing type.

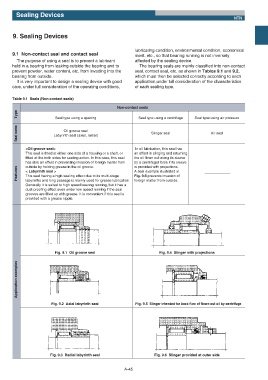

Table 9.1 Seals (Non-contact seals)

Non-contact seals

Type Seal type using a spacing Seal type using a centrifuge Seal type using air pressure

Seal name Labyrinth seal (axial, radial) Slinger seal Air seal

Oil groove seal

<Oil groove seal> In oil lubrication, this seal has

This seal is fitted at either one side of a housing or a shaft, or an effect in slinging and returning

fitted at the both sides for sealing action. In this case, this seal the oil flown out along its sleeve

has also an effect in preventing invasion of foreign matter from by a centrifugal force if its sleeve

outside by holding grease in the oil groove.

is provided with projections.

Features < Labyrinth seal > A seal example illustrated in

This seal having a high sealing effect due to its multi-stage

Fig. 9.6 prevents invasion of

labyrinths and long passage is mainly used for grease lubrication.

Generally it is suited to high speed bearing running, but it has a foreign matter from outside.

dust-proofing effect even under low speed running if the seal

grooves are filled up with grease. It is convenient if this seal is

provided with a grease nipple.

Fig. 9.1 Oil groove seal Fig. 9.4 Slinger with projections

Application examples

Fig. 9.2 Axial labyrinth seal Fig. 9.5 Slinger intended for back flow of flown-out oil by centrifuge

Fig. 9.3 Radial labyrinth seal Fig. 9.6 Slinger provided at outer side

A-45