Page 53 - needle bearings

P. 53

Bearing Handling

NTN

10. Bearing Handling

A rolling bearing is a precision part. It must be handled Furthermore, the bearing mount must be inspected to

very carefully to keep its preciseness unchanged. verify whether its dimensional accuracy, profile

Particularly the handling instructions given hereunder accuracy and surface roughness are within the

must be observed in handling. respective specified tolerance ranges.

Bearings are all unpacked before installing. In the

[1] Keeping bearing and other related parts clean case of using bearings with grease lubrication,

Foreign matters such as mist, dust, etc. would cause

generally they may be installed as are without

harmful affect on bearing running and life. To avoid washing off the rust inhibitor coated thereon.

such harmful effect, bearing and other parts mounted

Where a bearing is used with oil lubrication or the

adjacent to the bearing must be kept clean and, in lubricating function of a grease-lubricated bearing is

addition, handling tools, lubricant, washing oil, work

impaired by a mixture of grease and rust inhibitor,

environment, etc. must always be maintained in clean however, the bearing must be installed after complete

condition respectively.

removal of the rust inhibitor by clean washing oil.

[2] Careful handling It is not allowed to wash shield type and seal type

Any shock to a bearing in handling would result in bearings and one-way clutch.

surface flaw and indent of its raceway surface and

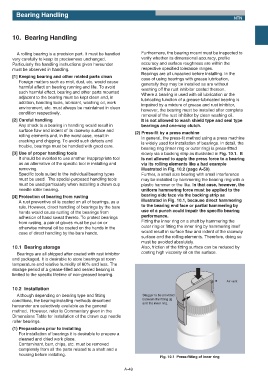

(2) Press-fit by a press machine

rolling elements and, in the worst case, result in

In general, the press-fit method using a press machine

cracking and chipping. To avoid such defects and

is widely used for installation of bearings. In detail, the

trouble, bearings must be handled with good care.

bearing ring (inner ring or outer ring) is press-fitted

[3] Use of proper handling tools slowly via a backing strip as illustrated in Fig. 10.1. It

It should be avoided to use another inappropriate tool is not allowed to apply the press force to a bearing

as an alternative of the specific tool in installing and via its rolling elements like a bad example

removing. illustrated in Fig. 10.2 (page A-50).

Specific tools suited to the individual bearing types Further, a small size bearing with small interference

must be used. The special-purposed handling tools may be installed by hammering the bearing ring with a

must be used particularly when installing a drawn cup plastic hammer or the like. In that case, however, the

needle roller bearing. uniform hammering force must be applied to the

bearing side face via the backing strip as

[4] Protection of bearing from rusting

A rust preventive oil is coated on all of bearings, as a illustrated in Fig. 10.1, because direct hammering

to the bearing end face or partial hammering by

rule. However, direct handling of bearings by the bare

hands would cause rusting of the bearings from use of a punch could impair the specific bearing

performance.

adhesion of hand sweat thereto. To protect bearings

from rusting, a pair of gloves must be put on or Fitting the inner ring on a shaft by hammering the

outer ring or fitting the inner ring by hammering itself

otherwise mineral oil be coated on the hands in the

case of direct handling by the bare hands. would result in surface flaw and indent of the raceway

surface and the rolling elements. Therefore, doing so

must be avoided absolutely.

10.1 Bearing storage Also, friction of the fitting surface can be reduced by

Bearings are all shipped after coated with rust inhibitor coating high viscosity oil on the surface.

and packaged. It is desirable to store bearings at room

temperature and relative humidity of 60% and less. The

storage period of a grease-filled and sealed bearing is

limited to the specific lifetime of non-greased bearing.

Air vent

10.2 Installation

Although depending on bearing type and fitting Stagger to be provided

between the fitting jig

conditions, the bearing installing methods described

and the inner ring.

hereunder are selectively available as the general

method. However, refer to Commentary given in the

Dimensions Table for installation of the drawn cup needle

roller bearings.

(1) Preparations prior to installing

For installation of bearings it is desirable to prepare a

cleaned and dried work place.

Contaminant, burr, chips, etc. must be removed

completely from all the parts related to a shaft and a

housing before installing.

Fig. 10.1 Press-fitting of inner ring

A-49