Page 51 - needle bearings

P. 51

Sealing Devices

NTN

Table 9.3 Clearances

9.2 Combined seals

Seal type Shaft diameter Radial Axial

Several seal types are used in combination for a seal clearance clearance

application under an environment where dust, water 50 and less 0.2ʙ0.4

Oil groove seal

content, etc. exist so much or for mechanical portions Over 50 to 200 0.5ʙ1.0

which are not allowed to be contaminated by lubricant 50 and less 0.2ʙ0.4 1.0ʙ2.0

leak. Labyrinth seal

Over 50 to 200 0.5ʙ1.0 3.0ʙ5.0

9.4 NTN seals

Special-purposed NTN seals are available for the

needle roller bearings.(Refer to Table 9.4 on page A-48.)

For the more detailed information refer to "Dimensions

Table" on page B-233.

9.5 Seal materials and corresponding operating

temperature ranges

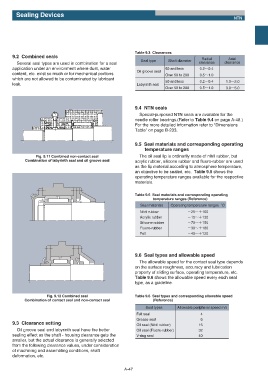

Fig. 9.11 Combined non-contact seal The oil seal lip is ordinarily made of nitril rubber, but

Combination of labyrinth seal and oil groove seal acrylic rubber, silicone rubber and fluoro-rubber are used

as the lip material according to atmosphere temperature,

an objective to be sealed, etc. Table 9.5 shows the

operating temperature ranges available for the respective

materials.

Table 9.5 Seal materials and corresponding operating

temperature ranges (Reference)

Seal materials Operating temperature ranges ˚C

Nitril rubber ʵ25ʙʴ100

Acrylic rubber ʵ15ʙʴ130

Silicone rubber ʵ70ʙʴ150

Fluoro-rubber ʵ30ʙʴ180

Felt ʵ40ʙʴ120

9.6 Seal types and allowable speed

The allowable speed for the contact seal type depends

on the surface roughness, accuracy and lubrication

property of sliding surface, operating temperature, etc.

Table 9.6 shows the allowable speed every each seal

type, as a guideline.

Fig. 9.12 Combined seal Table 9.6 Seal types and corresponding allowable speed

Combination of contact seal and non-contact seal (Reference)

Seal types Allowable peripheral speed m/s

Felt seal 4

Grease seal 6

9.3 Clearance setting

Oil seal (Nitril rubber) 15

Oil groove seal and labyrinth seal have the better Oil seal (Fluoro-rubber) 32

sealing effect as the shaft - housing clearance gets the V-ring seal 40

smaller, but the actual clearance is generally selected

from the following clearance values, under consideration

of machining and assembling conditions, shaft

deformation, etc.

A-47