Page 54 - needle bearings

P. 54

Bearing Handling

NTN

10.3 Post-installation running test

Bearing running test must be conducted on an installed

bearing to check whether it was installed correctly. In this

case, accelerating immediately the running speed up to

the rated speed must be avoided absolutely. Doing so

could result in damage of the bearing in the case of

imperfect installation and seizure of the bearing in the

case of inadequate lubrication. In testing, therefore, the

shaft or the housing must first be rotated by hand and

thereafter the shaft be rotated at low speed under no-load

condition by the driving power, unless any failure is

detected upon checking. After that, the running speed

Good example Bad example and load on the bearing must be accelerated and

increased gradually while checking the running condition.

Fig.10.2 Press-fit Running sound level and tone of a bearing can be

checked by a sound scope held in contact with the

bearing housing. The sound is normal if it is a pure sound

(3) Shrinkage fit

upon checking. In this case, high metallic sound or

This shrinkage fit method is to fit the inner ring on a irregular sound from the bearing, if any, reveals

shaft after dipping it in hot oil for thermal expansion of

occurrence of somewhat failure. In such a case, possible

its bore. This method is also widely used for cause of the failure can be presumed by measuring

installation of bearings. In heating the inner ring, low-

quantitatively vibration amplitude and frequency using a

corrosive mineral oil or the like is used. In this case, vibrometer.

the heated inner ring is natural-cooled down after

Generally bearing temperature is presumed from the

shrinkage-fit, but simultaneously it shrinks in axial circumferential temperature of a housing. However, it can

direction, too. Therefore, the inner ring must be

be judged more exactly if possible to measure directly the

pressed to the shaft shoulder until adequate cool- outer ring temperature by utilizing the oil hole thereof, etc.

down, so as not to allow a clearance between the

Needless to say, bearing temperature rises with elapse

inner ring and the shoulder. of the running time and reaches a constant level after a

In any case, however, it is not allowed to heat the

certain time. Rapid bearing temperature rise or continued

inner ring up to over 120˚C. temperature rise in excess to the constant level or

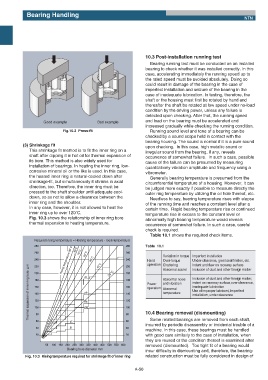

Fig. 10.3 shows the relationship of inner ring bore

abnormally high bearing temperature would reveals

thermal expansion to heating temperature. occurrence of somewhat failure. In such a case, careful

check is required.

Table 10.1 shows the required check items.

Required rising temperature = Heating temperature - room temperature

280 280 Table 10.1

260 80˚C 70˚C 60˚C 260 Variation in torque Imperfect installation

240 Rising temperature 90˚C 50˚C 40˚C 30˚C 240 Hand Over-torque Under-clearance, great seal friction, etc.

Thermal expansion of inner ring bore Жm 180 r6 180 Power Abnormal noise Inclusion of dust and other foreign matter,

operation Chattering

Indent and flaw on raceway surface

220

220

Inclusion of dust and other foreign matter

Abnormal sound

200

200

indent on raceway surface,over-clearance,

and vibration

inadequate lubrication

160

160

operation

Abnormal

Use of improper lubricant, imperfect

temperature

p6

140

140

installation, under-clearance

120

120

n6

100

80

80

Some related bearings are removed from each shaft,

60

60 k5 m6 100 10.4 Bearing removal (dismounting)

incurred by periodic disassembly or incidental trouble of a

40 j5 40

machine. In this case, these bearings must be handled

20 20 with good care similarly to the case of installation, when

they are reused or the condition thereof is examined after

50 100 150 200 250 300 350 400 450 500 550 600 removed (dismounted). Too tight fit of a bearing would

Bearing bore diameter mm

incur difficulty in dismounting and, therefore, the bearing-

Fig. 10.3 Rising temperature required for shrinkage fit of inner ring related construction must be fully considered in design of

A-50