Page 22 - needle bearings

P. 22

Load Rating and Life

NTN

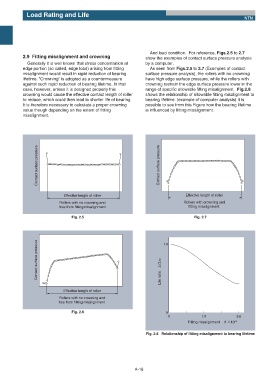

And load condition. For reference, Figs.2.5 to 2.7

2.9 Fitting misalignment and crowning show the examples of contact surface pressure analysis

Generally it is well known that stress concentration at by a computer.

edge portion (so called, edge load) arising from fitting As seen from Figs.2.5 to 2.7 (Examples of contact

misalignment would result in rapid reduction of bearing surface pressure analysis), the rollers with no crowning

lifetime. "Crowning" is adopted as a countermeasure have high edge surface pressure, while the rollers with

against such rapid reduction of bearing lifetime. In that crowning restrain the edge surface pressure lower in the

case, however, unless it is designed properly this range of specific allowable fitting misalignment. Fig.2.8

crowning would cause the effective contact length of roller shows the relationship of allowable fitting misalignment to

to reduce, which could then lead to shorter life of bearing. bearing lifetime. (example of computer analysis) It is

It is therefore necessary to calculate a proper crowning possible to see from this Figure how the bearing lifetime

value though depending on the extent of fitting is influenced by fitting misalignment.

misalignment.

Contact surface pressure Contact surface pressure

Effective length of roller Effective length of roller

Rollers with no crowning and Rollers with crowning and

free from fitting misalignment fitting misalignment

Fig. 2.5 Fig. 2.7

Contact surface pressure Life ratioɹL L10 1.0

Effective length of roller

Rollers with no crowning and

free from fitting misalignment

Fig. 2.6 0

0 1.0 2.0

Fitting misalignmentɹВʷ10 -3

Fig. 2.8 Relationship of fitting misalignment to bearing lifetime

A-18