Page 24 - needle bearings

P. 24

Calculation of Bearing Loads

NTN

3. Calculation of Bearing Loads

3.1 Load acting on shafts

The loads acting on the shaft to be supported with the

bearing must be determined for calculation of bearing

loads. These loads include the self-weight of rotor assy,

loads inevitably resulting from a machine in running,

loads arising from power transmission, etc. These loads

are mostly difficult to calculate though some of them can Ks

be calculated numerically and theoretically.

The following paragraphs describe how to calculate

the loads acting on a power transmission shaft as one of Kt

the main bearing applications.

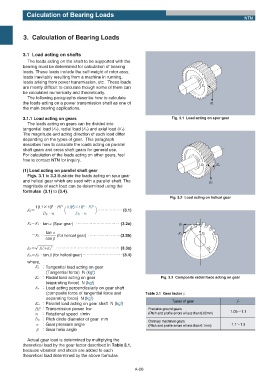

3.1.1 Load acting on gears Fig. 3.1 Load acting on spur gear

The loads acting on gears can be divided into

tangential load (Kt), radial load (Ks) and axial load (Ka).

The magnitude and acting direction of each load differ

depending on the types of gear. This paragraph

describes how to calculate the loads acting on parallel

shaft gears and cross shaft gears for general use.

For calculation of the loads acting on other gears, feel

free to contact NTN for inquiry.

Ks Ka

(1) Load acting on parallel shaft gear

Figs. 3.1 to 3.3 illustrate the loads acting on spur gear

and helical gear which are used with a parallel shaft. The

Kt

magnitude of each load can be determined using the

formulas (3.1) to (3.4).

Fig. 3.2 Load acting on helical gear

6

6

19.1ʷ10 ɾHP 1.95ʷ10 ɾHP

ʢ

ʣ

Ktʹʕʕʕʕʕʕʕʕʕ ʕʕʕʕʕʕʕʕʕ ʜʜʜʜʜʜ (3.1)

Dpɾn Dpɾn

KsʹKtɾtanЋ(Spur gear) ʜʜʜʜʜʜʜʜʜʜʜ(3.2a) Kt

tanЋ Ks

ʹKtɾʕʕʕʕ (for helical gear) ʜʜʜʜʜʜʜʜ(3.2b) Kr

cosЌ

Krʹ˽ʉʉʉ ʜʜʜʜʜʜʜʜʜʜʜʜʜʜʜʜ(3.3a) Dp

2

2

Kt Ks

KaʹKtɾtanЌ(for helical gear)ʜʜʜʜʜʜʜʜʜʜ(3.4)

where,

Kt ɿTangential load acting on gear

(Tangential force) N (kgf)

Ks ɿRadial load acting on gear Fig. 3.3 Composite radial force acting on gear

(separating force) N (kgf)

Kr ɿLoad acting perpendicularly on gear shaft

(composite force of tangential force and Table 3.1 Gear factor fz

separating force) N (kgf)

Types of gear fz

Ka ɿParallel load acting on gear shaft N (kgf)

HPɿTransmission power kw Precision ground gears 1.05ʙ1.1

n ɿRotational speed r/min (Pitch and profile errors of less than 0.02mm)

Dp ɿPitch circle diameter of gear mm

Ordinary machined gears

Ћ ɿGear pressure angle (Pitch and profile errors of less than 0.1mm) 1.1ʙ1.3

Ќ ɿGear helix angle

Actual gear load is determined by multiplying the

theoretical load by the gear factor described in Table 3.1,

because vibration and shock are added to each

theoretical load determined by the above formulas.

A-20