Page 56 - needle bearings

P. 56

Technical Data

NTN

11. Technical Data

11. 1 HL Bearing 11.1.2 HL surface

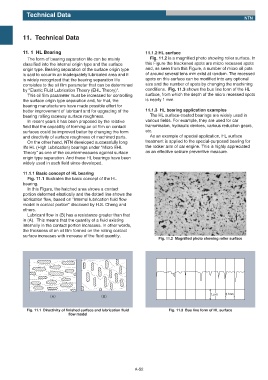

The form of bearing separation life can be mainly Fig. 11.2 is a magnified photo showing roller surface. In

classified into the internal origin type and the surface this Figure the blackened spots are micro recessed spots

origin type. Bearing separation of the surface origin type and, as seen from this Figure, a number of micro oil pots

is said to occur in an inadequately lubricated area and it of around several tens mm exist at random. The recessed

is widely recognized that the bearing separation life spots on this surface can be modified into any optional

correlates to the oil film parameter that can be determined size and the number of spots by changing the machining

by "Elastic Fluid Lubrication Theory (EHL Theory)". conditions. Fig. 11.3 shows the bus line form of the HL

This oil film parameter must be increased for controlling surface, from which the depth of the micro recessed spots

the surface origin type separation and, for that, the is nearly 1 mm.

bearing manufacturers have made possible effort for

better improvement of lubricant and for upgrading of the 11.1.3 HL bearing application examples

bearing rolling raceway surface roughness. The HL surface-treated bearings are widely used in

In recent years it has been proposed by the relative various fields. For example, they are used for car

field that the capability of forming an oil film on contact transmission, hydraulic devices, various reduction gears,

surfaces could be improved better by changing the form etc.

and directivity of surface roughness of machined parts. As an example of special application, HL surface

On the other hand, NTN developed successfully long treatment is applied to the special-purposed bearing for

life HL (High Lubrication) bearings under "Micro EHL the rocker arm of car engine. This is highly appreciated

Theory" as one of the countermeasures against surface as an effective seizure preventive measure.

origin type separation. And these HL bearings have been

widely used in each field since developed.

11.1.1 Basic concept of HL bearing

Fig. 11.1 illustrates the basic concept of the HL

bearing.

In this Figure, the hatched area shows a contact

portion deformed elastically and the dotted line shows the

lubrication flow, based on "Internal lubrication fluid flow

model in contact portion" disclosed by H.S. Cheng and

others.

Lubricant flow in (B) has a resistance greater than that

in (A). This means that the quantity of a fluid existing

internally in the contact portion increases. In other words,

the thickness of an oil film formed on the rolling contact

surface increases with increase of the fluid quantity.

Fig. 11.2 Magnified photo showing roller surface

1Жm 0.1mm

ʢAʣ ʢ Bʣ

Fig. 11.1 Directivity of finished surface and lubrication fluid Fig. 11.3 Bus line form of HL surface

flow model

A-52