Page 58 - needle bearings

P. 58

Technical Data

NTN

2) Inscribed circle diameter after complete bearing fit

11.3 Calculation Examples in the housing on actual machine

11.3.1 Shrinkage factor and post-installation

clearance of drawn cup needle roller bearing [1] Inscribed circle diameter in press-fitting of master ring

The recommended fit data for the standard bearings is

as described in Table 1 on page B-33. This paragraph

describes hereunder the calculation methods to be used

when the bearing fit conditions are reviewed in detail.

T

1) Calculation of bearing shrinkage factor

For the drawn cup bearings, the shrinkage factor is

calculated using the following method. H D

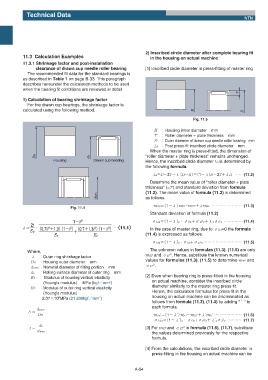

Fig. 11.5

H ɿHousing inner diameter mm

T ɿRoller diameter + plate thickness mm

D ɿOuter diameter of drawn cup needle roller bearing mm

Li ɿPost press-fit inscribed circle diameter mm

When the master ring is press-fitted, the dimension of

DH de "roller diameter + plate thickness" remains unchanged.

Housing Drawn cup bearing Hence, the inscribed circle diameter Li is determined by

the following formula.

LiʹDʵ2TʵЕʢDʵHʣʹʢ1ʵЕʣDʵ2TʴЕH ʜʜ(11.2)

Determine the mean value of "roller diameter + plate

thickness" (=T) and standard deviation from formula

(11.2). The mean value of formula (11.2) is determined

dnom as follows.

mLiʹʢ1ʵЕʣmDʵm2TʴЕmH ʜʜʜʜʜʜʜʜ(11.3)

Fig. 11.4

Standard deviation of formula (11.2)

1ʵS 2 МLi2ʹʢ1ʵЕʣ2ɾМD2ʴМ2T 2ʴЕ2МH 2 ʜʜʜʜʜ(11.4)

2t

2 ʜʢ11.1ʣ

Еʹɹɾ ʢ0.7S ʴ1.3ʣʢ1ʵt ʣʢ0.7ʴ1.3t ʣʢ1ʵS ʣ In the case of master ring, due to МH 2=0 the formula

2

2

2

E 2 ʴ

E 1 E 2 (11.4) is expressed as follows.

МLi2ʹʢ1ʵЕʣ2ɾМD2ʴМ2T 2 ʜʜʜʜʜʜʜʜʜʜ(11.5)

The unknown values in formulas (11.3), (11.5) are only

Where,

m T and М2T . Hence, substitute the known numerical

2

Е ɿOuter ring shrinkage factor

values for formulas (11.3), (11.5) to determine m2T and

DH ɿHousing outer diameter mm

М2T .

2

dnomɿNominal diameter of fitting portion mm

de ɿRolling surface diameter of outer ring mm

[2] Even when bearing ring is press-fitted in the housing

E ɿ Modulus of housing vertical elasticity

on actual machine, consider the inscribed circle

2

(Young’s modulus) MPa (kgfʗmm )

diameter similarly to the master ring press-fit.

E ɿModulus of outer ring vertical elasticity

Herein, the calculation formulas for press-fit in the

(Young’s modulus)

6

2

2.07ʷ10 MPa (21 200kgfʗmm ) housing on actual machine can be discriminated as

follows from formula (11.3), (11.4) by adding " " to

each formula.

dnom

S ʹʕʕʕ

DH mLi ʹʢ1ʵЕ ʣmDʵm2TʴЕ mH ʜʜʜʜʜʜʜ(11.6)

МLi 2ʹʢ1ʵЕ ʣ2ɾМD2ʴМ2T 2ʴЕ 2МH 2 ʜʜʜʜ(11.7)

de

t ʹʕʕʕ [3] For m2T and М2T in formula (11.6), (11.7), substitute

2

dnom

the values determined previously for the respective

formula.

[4] From the calculations, the inscribed circle diameter in

press-fitting in the housing on actual machine can be

A-54